Using earthbag construction for the NorCal Earthship garage has led to some interesting design possibilities. Our plan is to maximize the natural strengths of the earthen materials by shaping them into architecturally pleasing roman arches for the garage doors.

Rammed earth construction has been used for thousands of years. Over that time it has evolved to a modern building system that uses bags to form “superadobe” bricks. Combining this with barbed wire provides a robust construction method that was invented and perfected by the late Nader Khalili and his CalEarth institute.

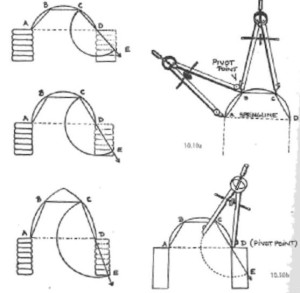

The primary reference that we used in our design was: Earthbag Building: The Tools, Tricks and Techniques,.by Kaki Hunter and Donald Kiffmeyer The methods are illustrated in the graphic immediately below and to the right, but details can be found in the book.

Adapted From Earthbag Building ISBN 978-0-86571-507-3

Starting with scaled sketches we identified the design that seems most appropriate and then modeled it in Solidworks. The goal was to identify the scale that seemed appropriate to accommodate even larger size vehicles.

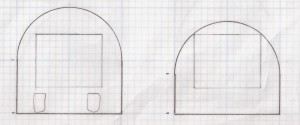

We started with the gothic arches using graph paper. The goal was to allow my jeep to fit comfortably into the garage and then even larger vehicles like full sized trucks. With the curvature of the arches, the doors needed to be taller than they would if they were only going to be square openings.

To reasonably accommodate the vehicles a gothic arch needed to be about 9.5 feet tall, but for true comfort 10.5 might be even more appropriate (see left most sketch in the graphic below). This kind of height would put us into some custom door design, which wasn’t our desire. Strictly off the shelf is what we would like to stick with for economic reasons.

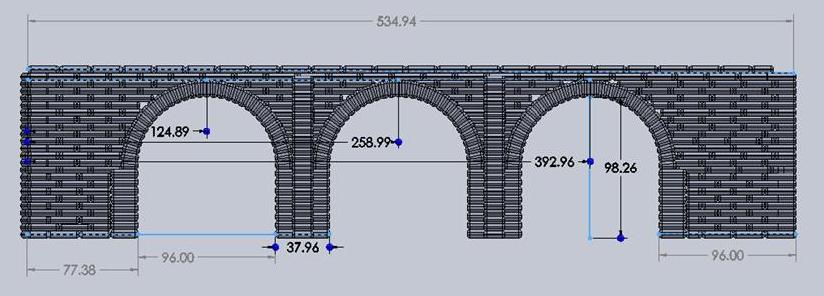

Moving on to roman arches the outcomes were more reasonable. An eight foot door would be possible, but not leave much leeway for larger vehicles (see left most sketch in the graphic below).

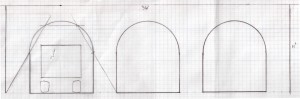

We settled on nine feet, which allows close to a foot and a half of clearance at the closest point. Taking the approach taught in Earthbag Builidng, we determined the amount of buttressing require to get robust structures and sketched the whole front elevation. Using eight foot wide doors and allowing at least 3 feet of buttressing between doors and the edges of the building leads to 36 feet on the front of the building.

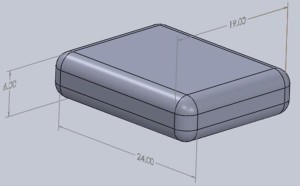

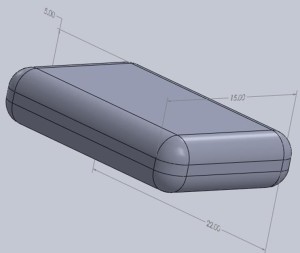

Basic building blocks

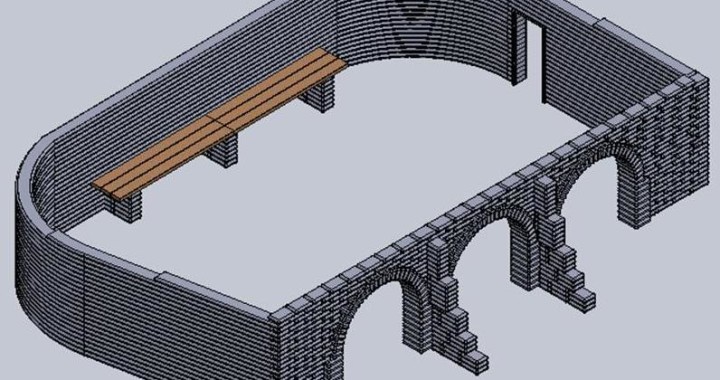

After the basic dimensions were established, we modeled the design in Solidworks. Dimensions for the earthbag bricks were the average sizes from Earthbag Building. Actual bags are shown in the graphic below, along with the tube cross-sections.

Front Elevation

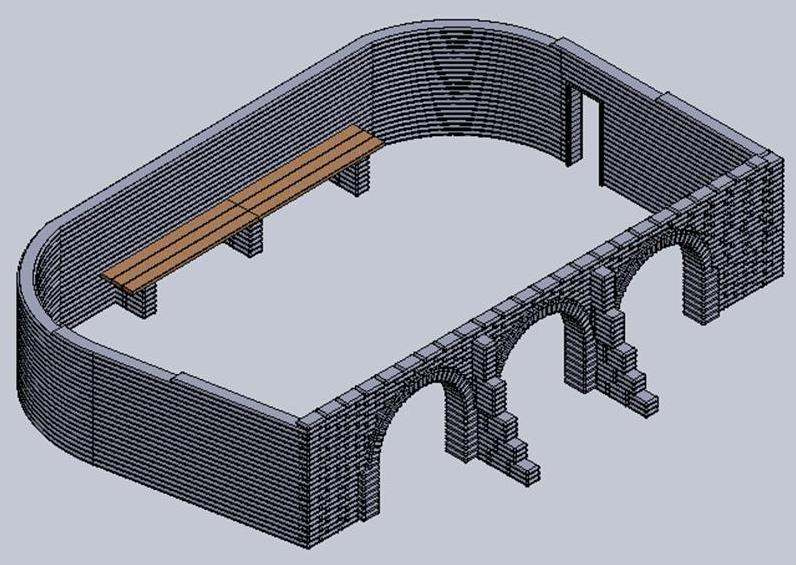

The outcome of the design is below. The actual structure is wider than the minimum 36 foot requirement. Extra space was to allow roomy parking stalls, as well as, a space for the laundry room on the right.

Isometric View

We will be finalizing the roof design soon and perhaps adding a frame inside the earthbag structure to support it. This is one option for dealing with CA building codes. The decision hasn’t been made yet, though, so check back for updates.

Hey, This article posted at this website is really good.